-

Product features and precautions for ...2021-8-30

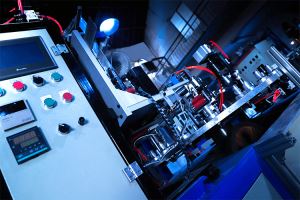

Product features of the rubber cap forming machine: 1. The plastic cap forming machine has a high degree of automation, simple operation and stable operation, which can effectively save enterprise costs and improve production efficiency. 2. Each single machine can work independently and has independent operation system, numerical control display and other electrical components to control and adjust various parameters and

-

Features and technical parameters of ...2021-8-23

Product features of rubber cap forming machine: 1. High degree of automation, simple operation, stable operation, can effectively save enterprise costs and improve production efficiency. 2. Each single machine can complete the work independently, and has its own

-

Convenience and Features of Capping M...2021-8-17

The lid closing machine is an automatic device developed for the one-piece flip. The lid closing machine is easy to use and covers a wide range. Its appearance avoids the inconvenience and time-consuming problems caused by manual operation. Today, the editor will introduce this to you in detail. machine. After injection molding, the one-piece cover is not closed, and the one-piece flip cover must be closed before it can be sold to the merchant

-

A brief overview of the capping machine2021-8-09

The capping machine is an ideal capping equipment, which can be used in bottle cap factories, packaging factories, food factories and daily chemical factories. It is convenient and accurate to use, avoiding the inconvenience and time-consuming problems caused by manual operation. Today, the editor will Introduce the cover closing machine in detail for you.

-

Operation specification of glue cap m...2021-8-02

The glue cap machine is a special equipment for packaging glue caps. The operation method of the glue cap machine will directly affect the packaging quality of the glue caps. So what operating specifications should we pay attention to? different

-

Equipment characteristics of glue cap...2021-7-26

The glue cap machine, also known as the automatic glue cap heat shrinking machine, is widely used to seal decorative products such as wine, rice wine, liquor, spices, water tanks. Features: 1. Simple structure and working principle, reliable operation and convenient maintenance.

-

Advantages of capping machine2021-7-21

The capping machine is an ideal capping equipment, which can be used in bottle cap factories, packaging factories, food factories and daily chemical factories. It is convenient and accurate to use, avoiding the inconvenience and time-consuming caused by manual operation. Today, Bian Xiao will tell Your advantage about the cap closing machine. Now plastic bottle caps are widely used, and many bottle caps are butterfly caps

-

Glue cap machine manufacturers bring ...2021-7-12

Glue cap machine manufacturers have brought you hot stamping skills. In order to attract customers' attention and influence their desire to buy, today's product packaging is getting more and more beautiful and dazzling. When customers buy products, they stop at each product The time on the website is no more than 1.8 seconds, and the products of a medium-sized planned supermarket are no less than 30,000 pieces.

-

Convenience and Features of Closing M...2021-7-05

Equipment features: 1. The automatic cap closing machine replaces manual operation, automatically inserts the gasket into the bottle cap, and improves production efficiency. 2. The gasket cover is flat, fast, efficient, and the product is safe and hygienic. 3. Equipped with no bottle cap, aluminum foil shutdown, etc. Safety protection device (optional). 4. The bottle cap is driven and transported, and the positioning is accurate.

-

The glue cap machine is very practica...2021-6-28

The equipment of the glue cap machine has the following characteristics: This series of label heat shrinkable film packaging machines are mainly used for the shrinkage of bottle labels of bottle-shaped, can-shaped and barrel-shaped cup-shaped products. It is suitable for glass bottles in food, medicine, cosmetics, pesticides and other industries. , Label shrinkage of plastic bottles, paper cups and other containers; shrinkage temperature intelligent control, electronic governor stepless adjustment of conveying speed

-

What are the advantages of the glue c...2021-6-21

1. In terms of raw materials, most of the raw materials used in the production of ordinary bottle caps are pure plastic or crystalline white materials, which are formed by high temperature one-step molding. The acquisition and matching of raw materials are relatively simple, and the style is relatively simple. In comparison, PVC heat shrinks Rubber bottle caps are made of ordinary bottle caps, resin as raw materials, and covered with a layer of PVC resin film.

-

Glue cap machine manufacturers briefl...2021-6-15

1. In terms of raw materials, most of the raw materials used in the production of ordinary bottle caps are pure plastic or crystalline white materials, which are formed by one-step molding at high temperature. The acquisition and matching of raw materials are relatively simple, and the style is relatively simple. In comparison, PVC heat shrinkable rubber The bottle cap is made of ordinary bottle cap, resin as raw material, and covered with a layer of PVC resin film.

-

Bottle caps launched by upper and low...2021-6-07

The hydraulic compression molding technique for making urea\/phenolic caps is to place a thermoset material into the cavity of a preheated mold and press it between 2 platens. The combined action of heat and pressure results in cross-linking in the material and the formation of small molecules, which causes the compound to fill the mold cavity and harden. After a period of time, the mold is opened and the molded product is removed.

-

Glue cap machine manufacturers briefl...2021-5-31

1. In terms of raw materials, most of the raw materials used in the production of ordinary bottle caps are pure plastic or crystalline white materials, which are formed by high temperature one-step molding. The acquisition and matching of raw materials are relatively simple, and the style is relatively simple. In comparison, PVC heat shrinks Rubber bottle caps are made of ordinary bottle caps, resin as raw materials, and covered with a layer of PVC resin film.

-

Features of online capping machine2021-5-24

The feature of the in-line capping machine is that it comprises a bracket, the vibration plate bottom plate of the bracket is provided with a first vibration plate and a second vibration plate, the material reclaiming plate of the bracket is provided with a reclaiming device, and the first vibration plate and the second vibration plate are connected with each other. A first capping device is arranged between the reclaiming devices, and the first vibrating plate and the second vibrating plate are used for feeding the first capping device;

-

What is the position of the glue cap ...2021-5-17

The equipment of the glue cap machine has the following characteristics: This series of label heat shrinkable film packaging machines are mainly used for the shrinkage of bottle labels of bottle-shaped, can-shaped and barrel-shaped cup-shaped products. It is suitable for glass bottles in food, medicine, cosmetics, pesticides and other industries. , Label shrinkage of plastic bottles, paper cups and other containers; shrinkage temperature intelligent control, electronic governor stepless adjustment of conveying speed

-

Description of technical advantages o...2021-5-10

As we all know, product packaging is one of the magic weapons to attract buyers' attention. How is the elegant outer packaging presented? It is to use a labeling machine. First, let's talk about the technical advantages of the online capping machine: 1. High speed, stability, and service life Long: All parts are made of world-renowned brands and related industrial control industry products. In addition, its unique closed design not only protects the operator, but also protects the equipment system itself, greatly extending the service life of the equipment.

-

The comparative analysis of the bottl...2021-4-30

Anyone who has bought a machine will know that they will encounter various types of choices when choosing, so they will encounter the first problem, that is, what is the difference between automatic and semi-automatic? Bottled water cap labeling machine is one of them. So what is the comparison between the bottled water cap labeling machine and the half-barrelled water cap labeling machine?

-

Features of the upper and lower cover...2021-4-19

The hydraulic compression molding technique for making urea\/phenolic caps is to place a thermoset material into the cavity of a preheated mold and press it between 2 platens. The combined action of heat and pressure results in cross-linking in the material and the formation of small molecules, which causes the compound to fill the mold cavity and harden. After a period of time, the mold is opened and the molded product is removed.

-

Perfect configuration mechanism of co...2021-4-12

The condiment cap assembly machine is a high-speed automatic capping machine designed according to the characteristics of the current condiment industry in my country. It is suitable for automatic capping, splitting and capping of various condiments. The whole machine adopts a mechanical synchronous power transmission system, and the movement coordination is accurate. , The equipment structure is reasonable, the speed is fast, the production efficiency is high, the failure rate is low, and the operation is simple.

电话:13063274639邮箱:925921075@qq.com

欢迎访问Tongcheng Saiwei Automatic Packaging Equipment Factory网站 LanguageLink_RopDown