-

Why is the glue cap machine indispens...2021-4-06

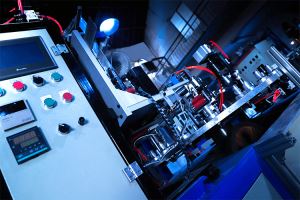

The equipment of the glue cap machine has the following characteristics: This series of label heat shrinkable film packaging machines are mainly used for the shrinkage of bottle labels of bottle-shaped, can-shaped and barrel-shaped cup-shaped products. It is suitable for glass bottles in food, medicine, cosmetics, pesticides and other industries. , Label shrinkage of plastic bottles, paper cups and other containers; shrinkage temperature intelligent control, electronic governor stepless adjustment of conveying speed

-

What requirements should the glue cap...2021-3-30

Most plastic caps are tinned lead skins, and the effect of tinning is to separate the lead from the wine. By the early 1990s, this "lead cap" had been gradually screened out, not because of the effect of lead on wine, but because of the effect of lead on wine. It is because of the negative impact of lead on the environment. Today's rubber caps are generally made of tin, aluminum, PVC plastic or aluminum-plastic composite materials.

-

How to detect the sealing function of...2021-3-22

Many outsiders may think that the sealing ability of the bottle cap is provided by the thread, but in fact, the thread of the bottle cap and the thread of the bottle mouth are clearance fit and do not have any sealing ability. There are 3 areas where the bottle cap can provide sealing ability, followed by The inner seal, outer seal and top seal of the bottle cap. Each sealing area has a certain amount of deformation with the bottle mouth

-

What are the advantages of the cappin...2021-3-08

Nowadays, plastic bottle caps are widely used, many types of bottle caps are butterfly caps, and they are all produced by injection molding machines. The injection molded butterfly caps are now open, but the product must be turned over and tightly closed after injection molding Closed, injection molded products are ideal. However, manual capping is too costly

-

The glue cap machine analyzes the sys...2021-2-28

The main body of the automatic plastic cap forming machine is equipped with an automatic hot stamping system, which can continuously hot stamp exquisite patterns and characters on the PVC heat shrinkable film and aluminum-plastic laminating materials. The feeding of anodized paper is controlled by a synchronous motor. Drawing system: this machine Equipped with a wire drawing automatic sticking device, the wire drawing and wire feeding are controlled by a stepper motor, and the width is adjustable between 1-10 mm.

-

The characteristics of the glue cap m...2021-2-19

Features of the glue cap machine: 1. Simple structure and working principle, simple operation and reliable work. 2. In terms of maintenance, at least the equipment has a long service life. 3. Frequency conversion speed regulation, the working speed can be adjusted according to different production speeds. 4. Temperature Controlled by thyristor, the temperature fluctuation of PVC rubber cap heat shrinking machine is small

-

Reasons for different prices of wine ...2021-2-06

The sealing of wine requires 2 steps, one is to plug the bottle mouth with a stopper=the other is to seal with a glue cap machine, these two steps are very important. Therefore, the glue cap machine is very important, and its application has also become very important It is difficult to be universal. Because of its high production efficiency and low price, it is acceptable to everyone, so it is very popular. The price is the direct reason that affects consumers.

-

Application and requirements of glue ...2021-1-31

At the beginning, most of the rubber caps were tin-plated lead sheets, and the effect of tin-plating was to separate lead and wine. In the early 1990s, this "lead cap" was gradually screened out, not because of the influence of lead on wine, It is because of the negative impact of lead on the environment. Today's rubber caps are generally made of tin, aluminum, PVC plastic or aluminum-plastic composite materials.

-

Cover machine manufacturers take you ...2021-1-25

The lid closing machine manufacturer will show you the application of UV pad printing technology. The advantages of the cup pad printing machine have won the favor of those enterprises that are applying for environmental management certification, but we have to admit that the cup pad printing machine does not Eliminate environmental damage. Part of the closed solvent in the oil cup achieves a dynamic balance inside the oil cup

-

What is the design of the closing man...2021-1-18

Flip-top plastic bottle caps have entered the daily chemical products of thousands of households. Since most of the bottles containing daily chemical products are not reused, the market demand is large. Considering various factors, especially the machine occupied by the cover on the machine tool When the injection molding machine was used, a new solution was proposed, that is, after demolding, it was directly grasped by the manipulator and closed outside the injection molding machine.

-

High-quality lid closing machine manu...2021-1-11

At present, plastic bottle butterfly caps are widely used in shampoo bottles and cosmetic bottles. At present, plastic bottle butterfly caps are all produced by injection molding machines. The butterfly cap is opened during injection molding, but the finished product must be turned over and closed after injection molding. On is ideal. Some butterfly caps need to be inspected for defective product and oiled before the flip cap is closed.

-

The convenience brought by the lid cl...2021-1-04

1. Scope of application: It is mainly suitable for flip caps, oil caps, vinegar caps, cosmetic caps and other types of bottle caps. The cap closing machine is an automatic device developed for the one-piece flip cap. The one-piece flip cap is not closed after injection, and must be closed to supply the Manufacturers. Due to the slow speed of manual capping, low efficiency, and insufficient capping effect, which increases the cost of manufacturers, it is necessary to speed up the efficiency of the capping machine.

-

How to choose the filling line plasti...2020-12-21

The principle of high productivity and good product quality: Productivity directly reflects the production capacity of the production line. Therefore, the higher the productivity, the better the economic benefits. In order to improve product quality, we should choose the principle of high equipment precision and high degree of automation to serve production Process. First, it should be based on the nature of the filling material

-

The glue caps produced by the glue ca...2020-11-16

The glue cap machine produces bottle sealing caps, which involves the field of packaging anti-counterfeiting. It has a laser rod longitudinally attached to the inner side of the main material of the rubber cap, and a V-shaped hob indentation at the attached part, which causes physical damage to the used laser rod. , It is convenient to open manually. There is a dashed through hole that runs through the main material of the rubber cap longitudinally at other positions where the laser rod is not attached.

-

The manufacturer of the capping machi...2020-10-24

Many outsiders may think that the sealing ability of the bottle cap is provided by the thread, but in fact, the thread of the bottle cap and the thread of the bottle mouth are clearance fit and do not have any sealing ability. There are 3 areas where the bottle cap can provide sealing ability, followed by The inner seal, outer seal and top seal of the bottle cap.

-

The cap closing machine manufacturer ...2020-10-20

We should be familiar with this control system of PLC. For packaging machinery, this control system is getting more and more attention. For our machinery and equipment, this control system will be used in production. Now many enterprises in order to cooperate with the production of the assembly line, Start choosing machines with a higher degree of automation to use.

-

How the condiment cap assembly machin...2020-10-14

In the process of continuous advancement and development, with the continuous development of science and technology, the competition of automatic sauce packaging machines has become more and more fierce, and in this commodity market, automatic sauce packaging machines have used its strong strength to seize more More opportunities for development, so as to develop itself better. Sauce automatic packaging machine has brought people more suitable packaging

-

Reasons for different prices of wine ...2020-10-09

The sealing of wine requires 2 steps, one is to plug the bottle mouth with a stopper=the other is to seal with a glue cap machine, these two steps are very important. Therefore, the glue cap machine is very important, and the application of the glue cap machine also changes It is very common. Because of its high production efficiency and low price, everyone can accept it, so it is very popular.

-

The manufacturer of the capping machi...2020-9-21

Many outsiders may think that the sealing ability of the bottle cap is provided by the thread, but in fact the thread of the bottle cap and the thread of the bottle C are clearance fit, without any sealing ability. There are 3 areas where the bottle cap can provide the sealing ability. followed by the inner seal, outer seal and top seal of the bottle cap

-

The use and requirements of glue cap ...2020-9-14

At the beginning, most of the rubber caps were tin-plated lead sheets, and the effect of tin-plating was to separate lead and wine. In the early 1990s, this "lead cap" was gradually screened out, not because of the influence of lead on wine, It is because of the negative impact of lead on the environment. Today's rubber caps are generally made of tin, aluminum, PVC plastic or aluminum-plastic composite materials.

电话:13063274639邮箱:925921075@qq.com

欢迎访问Tongcheng Saiwei Automatic Packaging Equipment Factory网站 LanguageLink_RopDown