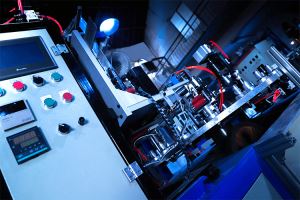

The equipment of the glue cap machine has the following characteristics: This series of label heat shrinkable film packaging machines are mainly used for the shrinkage of bottle labels of bottle-shaped, can-shaped and barrel-shaped cup-shaped products. It is suitable for glass bottles in food, medicine, cosmetics, pesticides and other industries. , label shrinkage of plastic bottles, paper cups and other containers; the shrinkage temperature is intelligently controlled, the electronic governor adjusts the conveying speed steplessly, and the unique conveying device of the cap shrinking machine ensures smooth conveying, and 360-degree rotating heating ensures uniform shrinkage.

Technical parameters of bottle cap shrinking machine Power supply voltage: 220V\/50-60HZ Power: 7KW Furnace size: 1000x 150x 150 mm Large package size: 4 sets of 105mm350mm·h Conveying motor: AC90W\/220V Conveying speed: 0-10m\/min conveying load : 15KG Applicable Shrink Film: POF, PVC, PP Machine Weight: Expansion Knowledge: The shrink machine wraps the product or package with shrink film. After heating, the shrink film wraps the product or package tightly, indicating that the goods are moisture-proof and pollution-proof after heating and packaging , to protect the goods from external impact, and has a certain cushioning performance, especially when packing fragile goods, it can prevent splashing when the container is broken. In addition, it can reduce the possibility of product disassembly and theft.

Rubber caps, also known as heat-shrinkable sealing caps, are made of PVC heat-shrinkable caps through various processes. The product can be hot-stamped with various colors and patterns, and can be used as a product seal. It has the functions of safety, hygiene, anti-counterfeiting and beautiful appearance. .Rubber bottle cap products are mainly used for mechanized packaging of alcoholic beverages, drinking water and other products.

The use of rubber bottle caps in commodities not only improves the grade of the product, but also symbolizes the identity of the product. The product has high shrinkage rate, low temperature required for shrinkage, good tightness to packaged goods after heat shrinkage, and is not easy to fall off. Advantages. Therefore, this product is now a widely used sealing product in the market.

Rubber cap products also have a good publicity effect, and can be printed with exquisite patterns, which can be used for product identification, publicity and beauty. Therefore, they are now widely used in various cosmetics, electronic products, liquor, beverages and other industries.