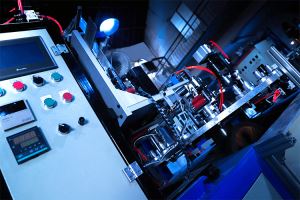

The operation requirements of the glue cap machine

2022-07-12 Tongcheng Saiwei Automatic Packaging Equipment Factory

The glue cap machine is a special equipment for packaging glue caps. The operation method of the glue cap machine will directly affect the packaging quality of the glue caps. So what operating specifications should we pay attention to? The following editor will tell you about it.

1. Check whether there are foreign objects on the machine, whether the rubber used is consistent with the product, and whether the circuit is normal.

2. Turn on the power switch (turn right → turn on, turn left → turn off), the machine will automatically heat up to 330 degrees Celsius.

3. Reset the machine. Press the "Emergency Reset" button to reset the machine settings.

4. Adjust the height of the capping machine, which is controlled by the manual adjuster B at the back, and the height is consistent with the height of the bottle. Before the automatic use, the bottle must be photographed with a second electric eye. In order to prevent the cap from being used on the shrinking machine for too long Long, you can manually separate the bottle with the rubber cap from the shrinking machine and send it away with a conveyor belt. Every time the machine is turned on, press the reset button. And every time you press the reset button, you can start the machine. The front door can be It can be turned on manually, or it can be turned off completely automatically.

5. Select the machine state, and press the automatic door button (turn right) in the manual state.

6. After the work is completed, the button (STOP CONVOYER) closes the chain, the button (STOP) closes the machine, and then the power is turned off.

The above are the operating requirements of the glue cap machine, so everyone must operate according to the requirements.